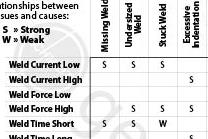

Issue/Cause Chart

Use this matrix as a quick reference to link common welding issues with standard causes (Interactive and printable PDF).

Missing Weld

Missing welds may be the result of operator placement mistakes, or the result of machine errors in performance or settings.

Undersized Weld

Undersized welds can be the product of dirty or damaged parts and materials, or of incorrect welding setups.

Stuck Weld

Electrode wear, low weld current and high weld force may cause “stuck welds,” when only a slight, weak bond is formed.

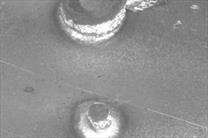

Excessive Indentation

High weld current, high weld force and long squeeze and hold times may cause deep indentations that do not meet specifications.

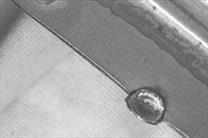

Expulsion/Burn-Through

Issues with high electrode follow-up, high current and welds too close to the edge may cause the expulsion of molten metal during welds.

Cracks and Holes

High current, low force, expulsion and other systematic problems may cause cracks and holes in welds.

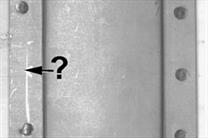

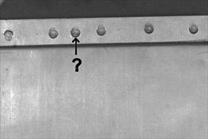

Mislocated/Edge Welds

Edge welds are often the result of electrode misplacement, trouble with access to weld areas, or part defects.

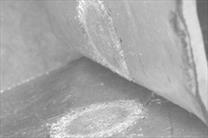

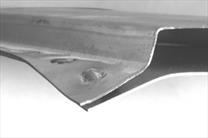

Sheet Metal Distortion

Problems with weld force, fixture placement and access to weld areas may cause distortion in workpieces and stampings.

Extra Welds

Additional unintended welds are usually the result of incorrect stampings or operator, robot or fixture error.

Inconsistent Welds

Variances in stampings and uneven electrical or mechanical connections may cause inconsistent resistance welds.

Brittle Welds

A weld that fractures with little plastic deformation may be caused by long hold times or problems with the stamping alloy chemistry.

Non-Round Welds

Non-round welds may be caused by electrode wear, issues with tip alignment, or dirty workpieces.

Poor Class A Appearance

Issues with required Class A appearances are often concurrent with a number of other issues, such as weld consistency and quality.

Stuck Electrodes

Electrodes, stampings or fasteners may weld together unintentionally after long hold times, incorrect materials or stamping coatings.

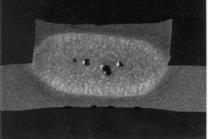

Interfacial Separation

Separation along the original weld plane (rather than tearing at a weld button) occur when stampings are stronger than the weld nugget.

Resistance Spot Welding Defect Troubleshooting Guide

The WeldHelp Resistance Welding Troubleshooting Guide is written for operators and engineers to help diagnose and solve common spot welding defects and issues, projection welding and seam welding applications. Consider it an experienced second opinion in a specialized field. Select an issue above or, if you suspect a cause creating multiple issues, check out the most common causes below.

Start with the WeldHelp Issue and Cause Matrix to help find solutions to common welding issues. Save the interactive .pdf file to your computer or print it out to use as a quick reference.

Common Causes of Resistance Spot Welding Defects

Weld Control/PLC Programming

- Weld Current Low

- Weld Current High

- Weld Force Low

- Weld Force High

- Weld Time Short

- Weld Time Long

- Squeeze Time Short

- Hold Time Short

- Hold Time Long

- Poor Tip Follow-Up

Equipment Selection

- Wrong Transformer

- Wrong Cables or Shunts

- Incorrect Cylinder

- Incorrect Hoses

- Wrong Electrodes (Tips)

- Incorrect Tip Dressing

- Wrong Shank

- Malfunctioning or Incorrect Air or Hydraulics

- Poor Mechanical Connections

- Poor Electrical Connection

Human Error and Project Set-Up Error

- Electrode Wear

- Incorrect Electrode Alignment

- Electrode Faces Not Parallel

- Electrode Skidding or Sliding

- Dirty Welding Materials

- Excessive Sealer

- Poor Part Fit-Up

- Poor Weld Access

- Shunting of Guns or Parts

- Incorrect Materials or Coatings

- Damaged Part

- Weld Flange Small

- Welds Mislocated

- Inadequate or No Gun Equalization

- Incorrect Tests

- Incorrect Workpiece

- Insufficient Cooling