Kyokutoh Tip Monitors

Tip dressing helps ensure weld quality and consistency in spot welding by returning the weld cap to a consistent size, location and surface. But are you confident in your tip dressing quality? A tip dress cycle can fail due to cutter wear, chatter, debris on the dressed face and more. These issues can lead to bad welds, bad parts, and expensive fines from downstream customers.

Kyokutoh Tip Monitors inspect resistance welding cap faces after each tip dressing cycle to ensure the electrode is ready for another round of consistent welds.

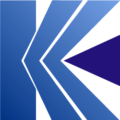

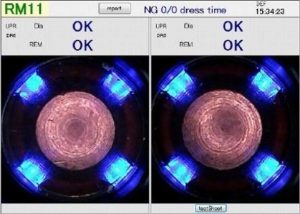

After each dressing cycle, the weld gun closes on the tip monitor unit (often mounted like a sidecar to the tip dresser). The Tip Monitor takes a photo and measures the consistency and shape of the weld face, and alerts users to out-of-spec dress cycles. The Kyokutoh Tip Monitor stores each photo for traceability.

The Tip Monitor is available in a network-connected version, the TMN-01, and a stand-alone version, the TMR-01. Up to 50 TMN-01 units can connect to a single computer via EtherNet (or 15 via CC-link or DeviceNet). The TMR-o1 only requires a computer for initial setup.

The Tip Monitor is also available with a retractable lens cover (rendering below, right) to keep the unit clean between uses.

G.E. Schmidt is a proud distributor of Kyokutoh Tip Dressers and Tip Changers, but the Kyokutoh Tip Monitor works with any installed tip dresser manufacturer.

For more information or to discuss your application, use the form below, email sales (at) geschmidt.com.