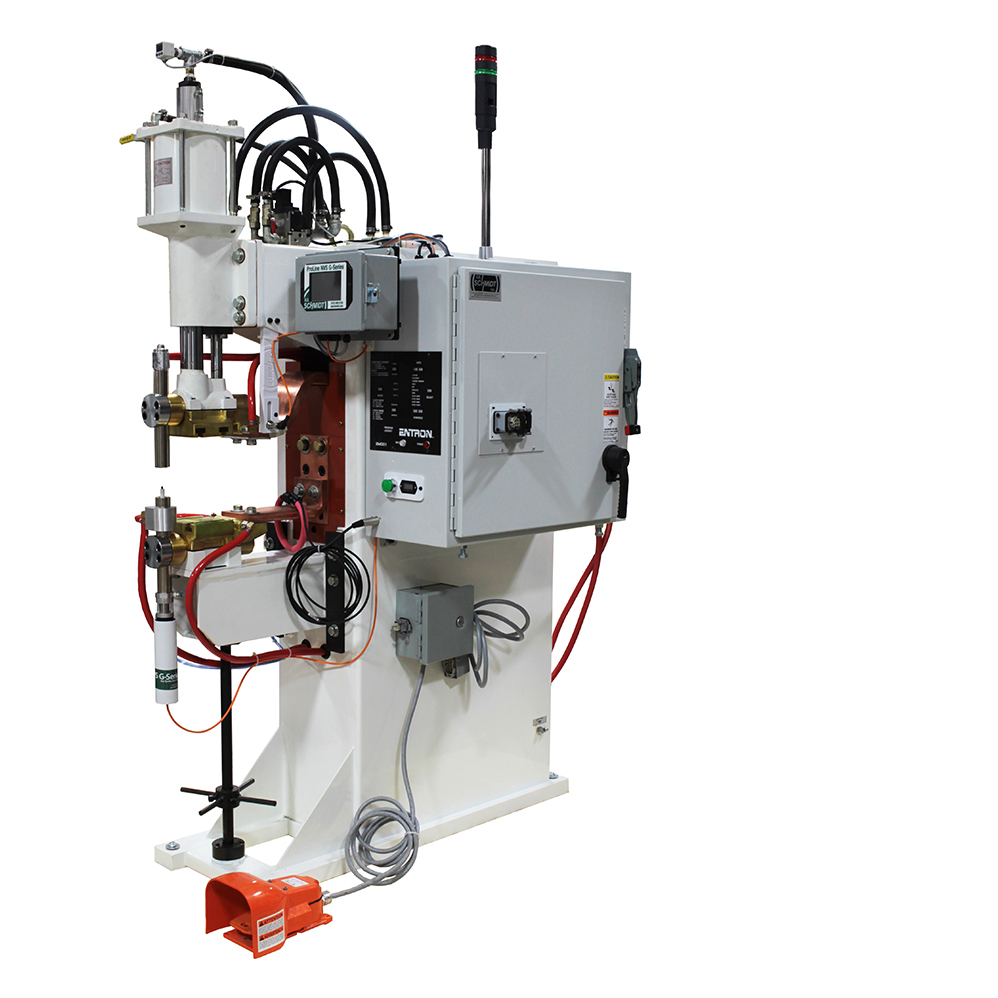

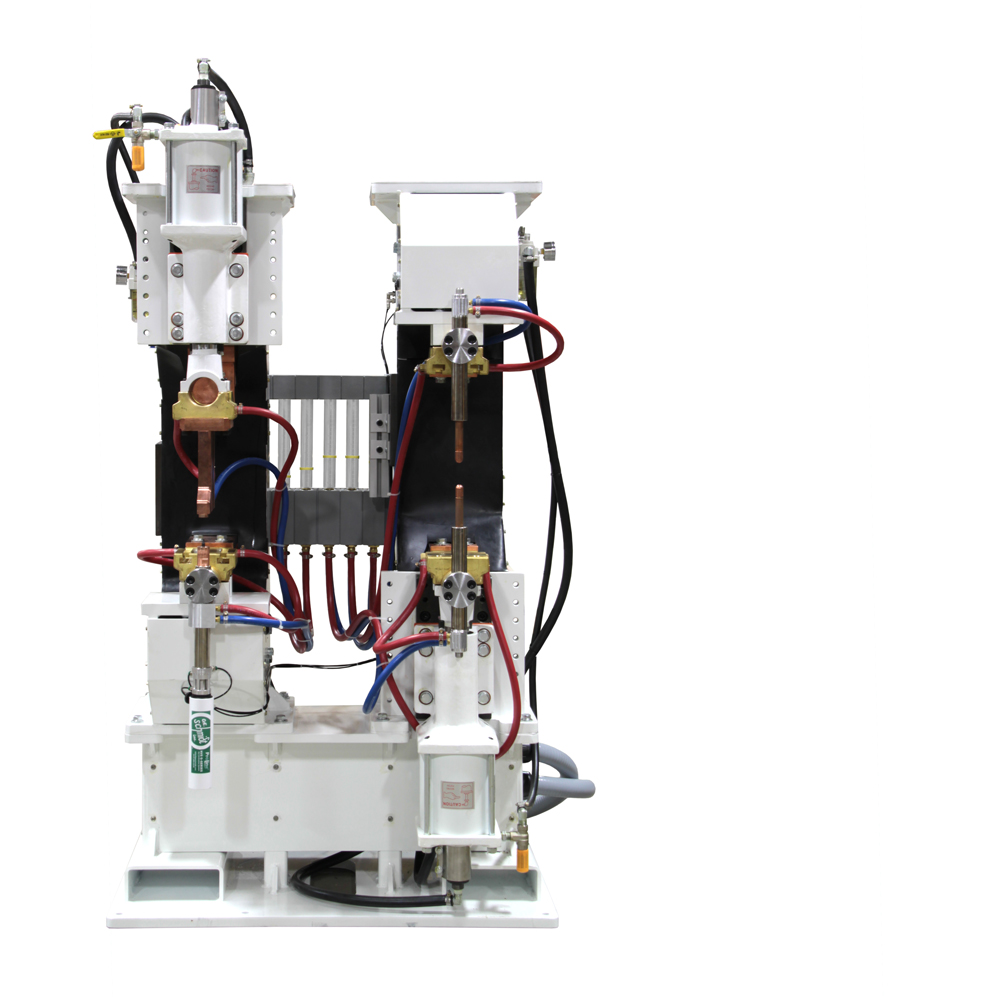

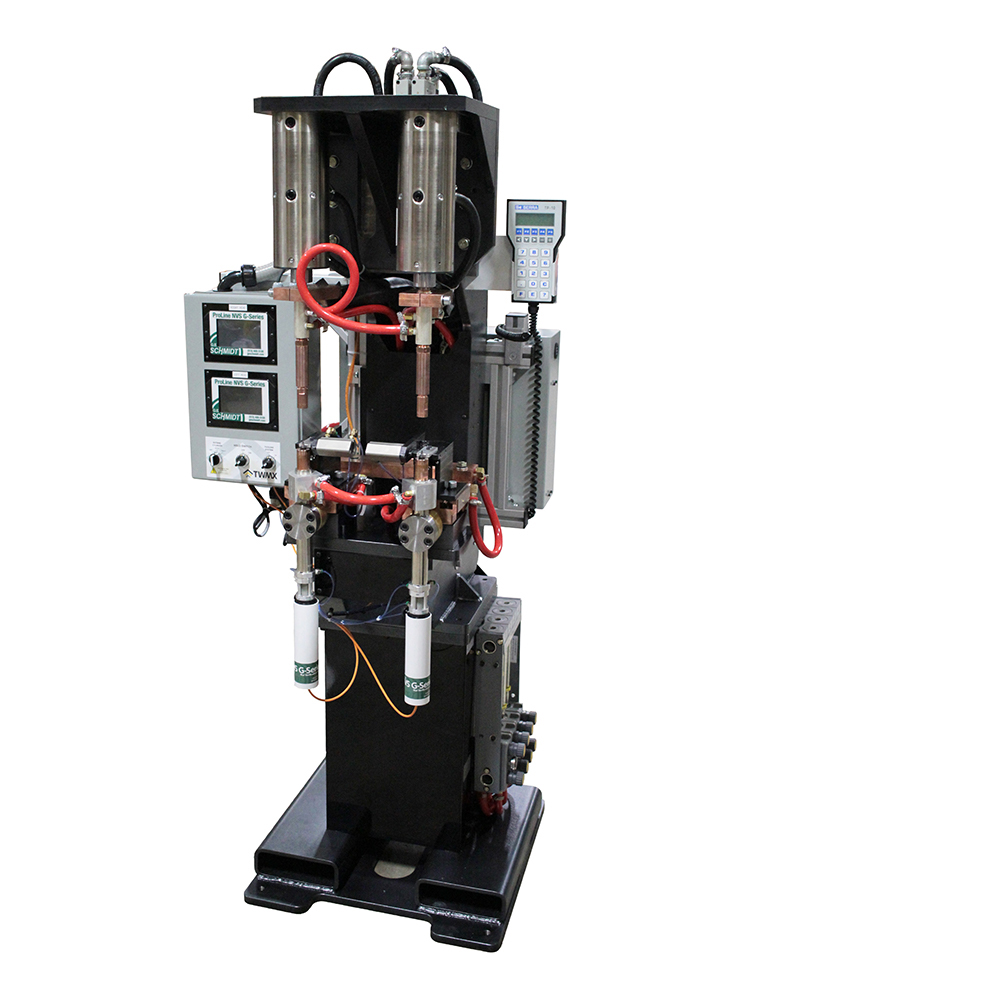

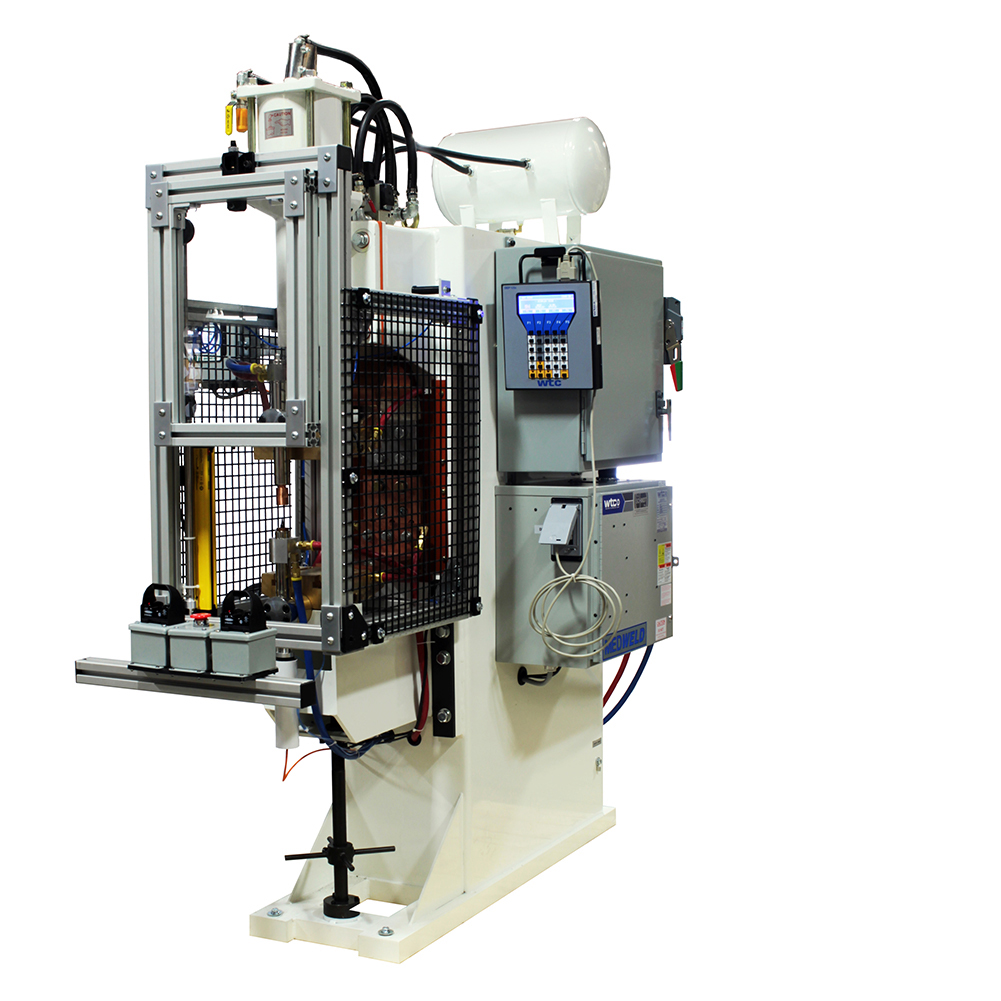

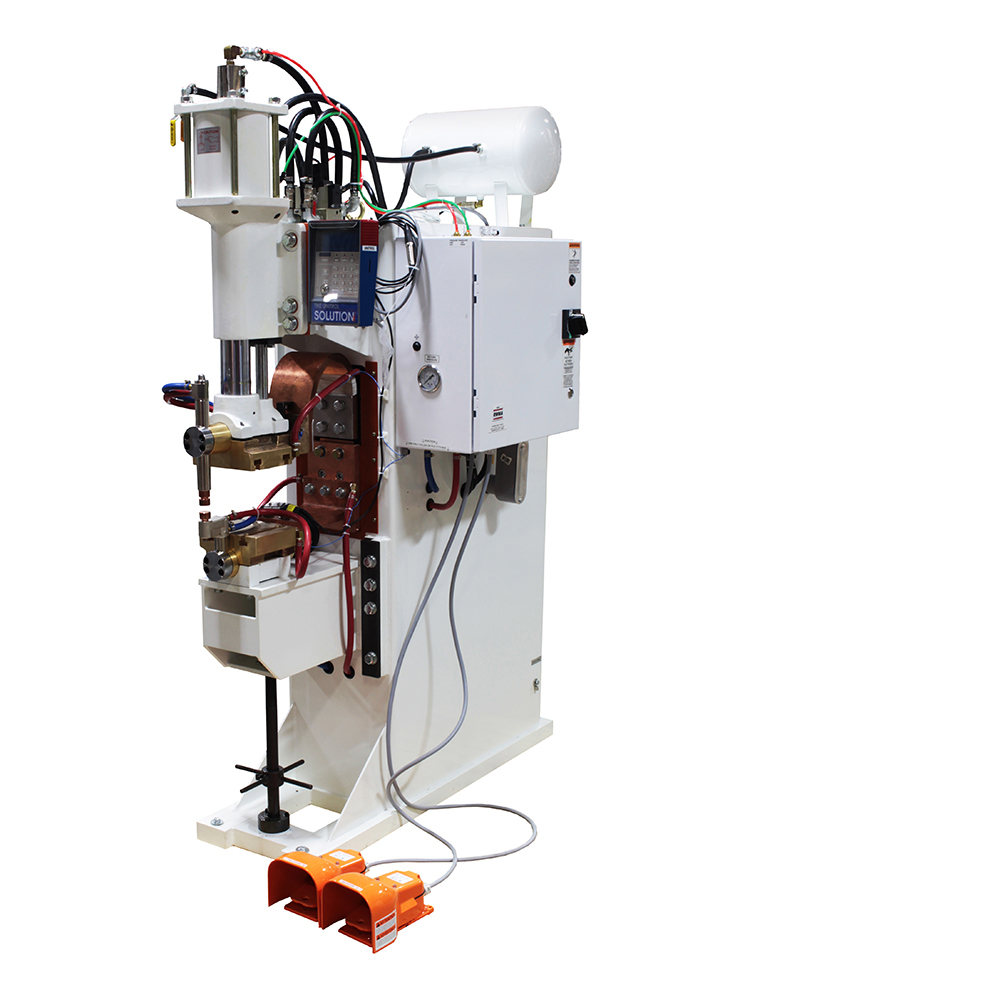

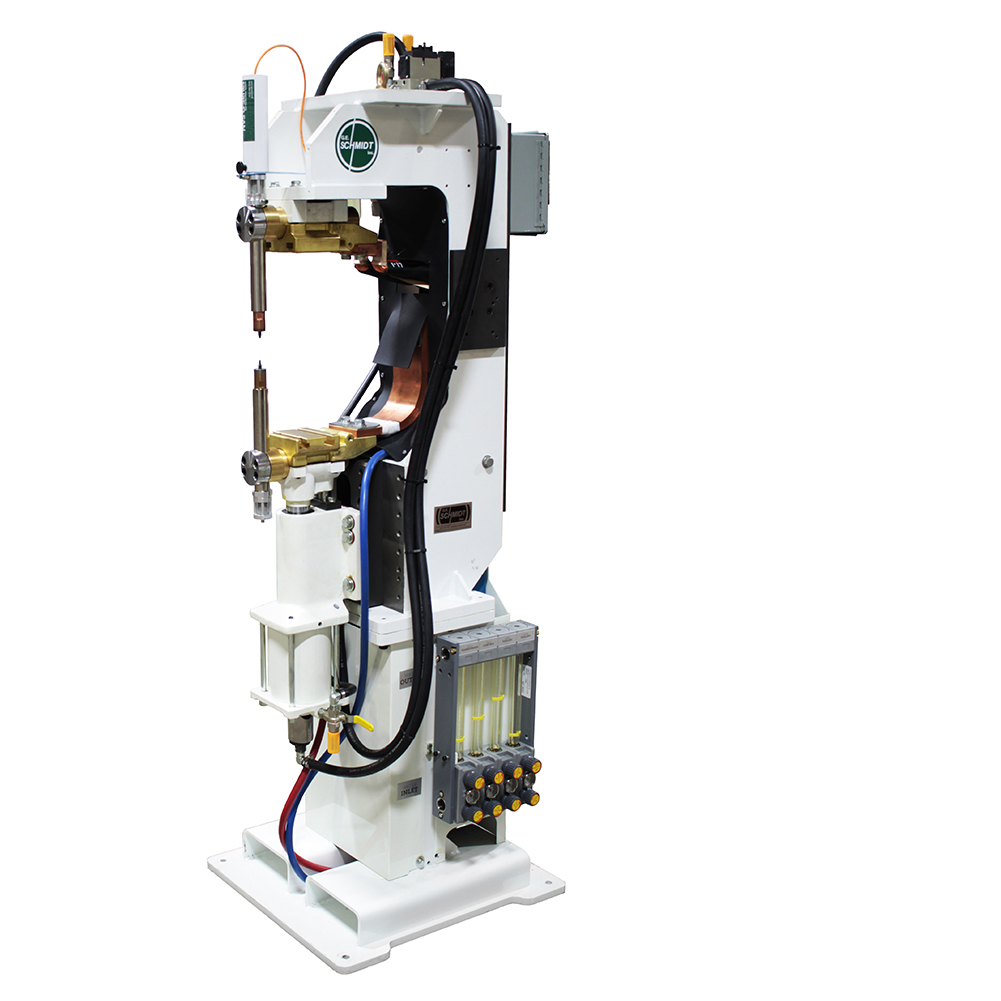

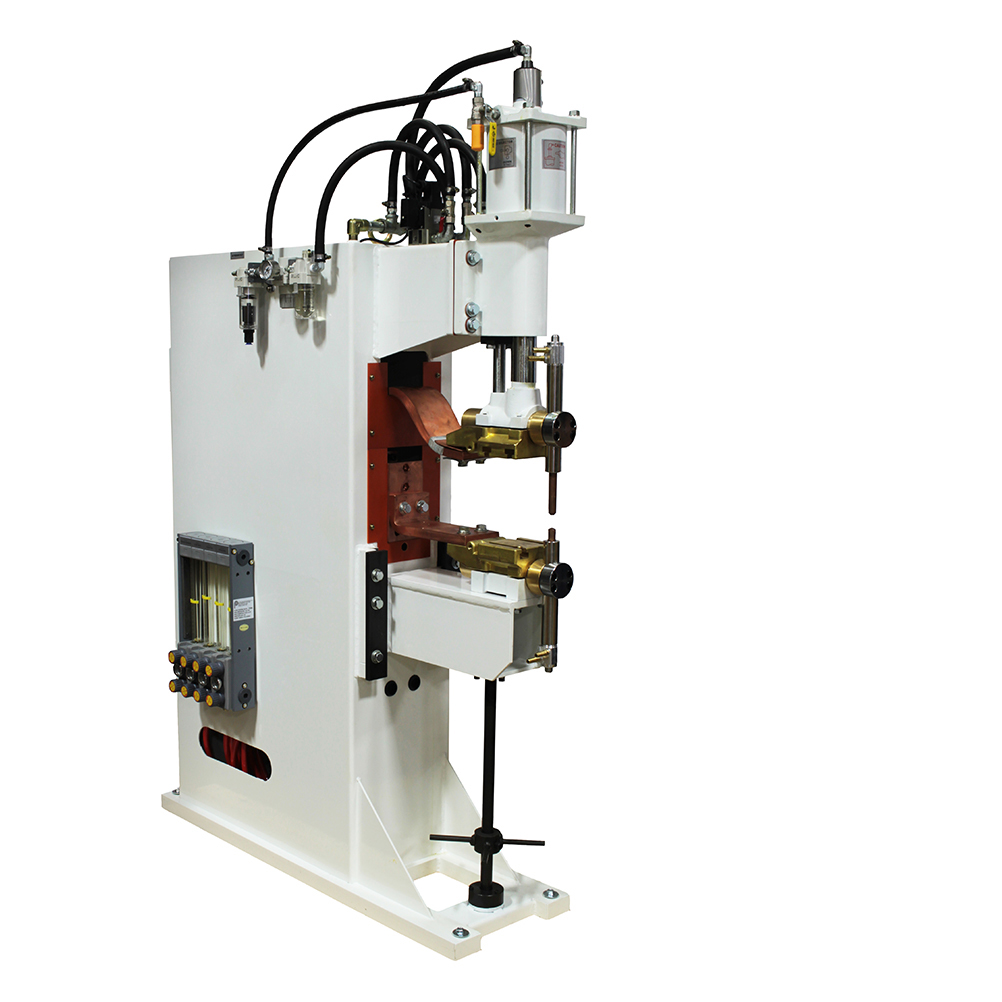

ProLine Pedestal Spot and Projection Welders

Using the latest quality control and safety technology, G.E. Schmidt provides the best-value pedestal resistance welder in the market for both projection welding and spot welding applications. We offer standalone welders, or we can integrate them with nut feeders, quality sensing systems, custom tooling and safety devices for delivery as plug-and-play devices with the best lead times in the industry.

| Standard Specs | Size 1 | Size 2 | Dual-Head | SD Adaptive Frame |

|---|---|---|---|---|

| Throat Depth (in.) | 18 | 18, 24, or 36 | 18 | 15.5 |

| Horn Diameter (in.) | 2.75 | 2.75 | 2.75 | 2.75 |

| Cylinder Diameter (in.) | 5.5 | 6.25 | 5.5 | 5.5 |

| Cylinder Stroke (in.) | 3.0 | 3.75 | 3.0 or 4.0 | 3.0 or 4.0 |

| Platen Size (in.) | 4.7 x 4.0 (x2) | 7.0 x 6.3 (x2) | 4.7 x 4.0 (x2) | 4.7 x 4.0 (x1) |

| Max Force (lbs. @ 80 PSI) | 1,900 | 2,400 | 1,900 | 1,900 |

| Dimensions (WxDxH, in.) | 14 x 47 x 70 | 15 x 54 x 78 | 36 x 46 x 70 | 22 x 27 x 75 (pedestal) 14 x 23 x 49 (bench) |

| Transformer Power (KVA) | 5 – 150 | 100 – 300 | 5 – 150 | 80 – 120 |

| Electrical Input | 220 or 440 VAC, 60 or 50 Hz | 220 or 440 VAC, 60 or 50 Hz | 220 or 440 VAC, 60 or 50 Hz | 220 or 440 VAC, 60 or 50 Hz |

ProLine Welders are proudly designed to work with:

RoMan Manufacturing AC & MFDC Transformers

Entron Weld Controls

WTC Weld Controls

Unitrol Simplicity Weld Controls and Soft Touch Safety Systems

… And many other quality component manufacturers to meet your company’s standards.