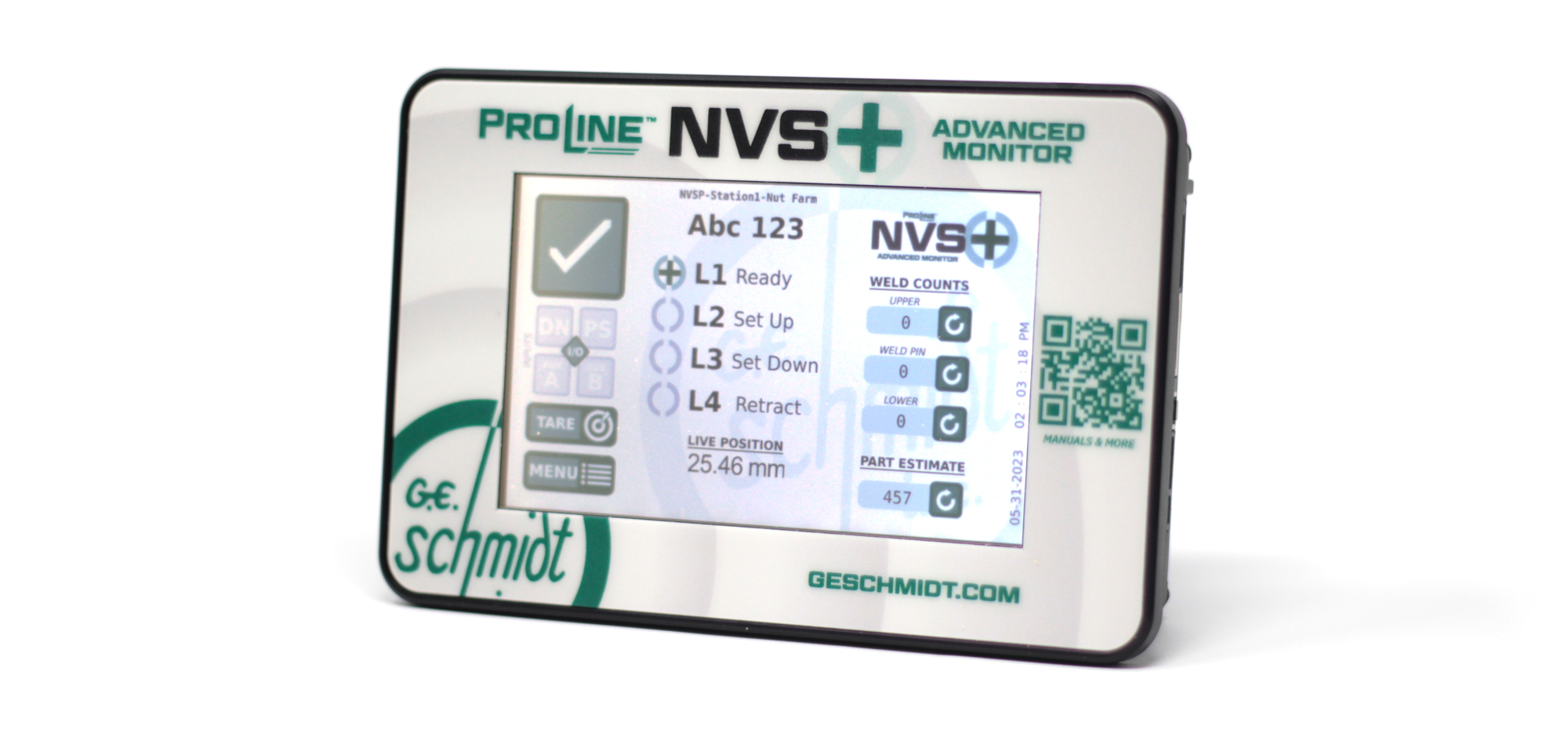

NVS+ Advanced Monitor

The next generation of nut welding quality control

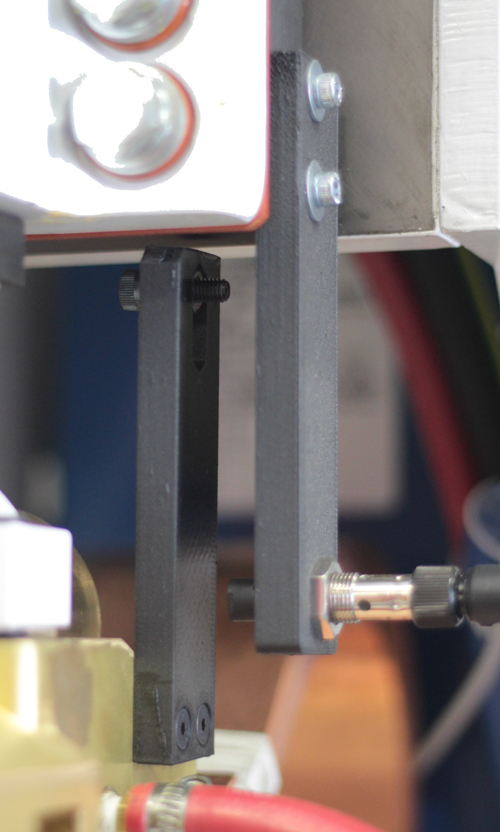

Double-Nut Sensor

Double-nut issues can occur due to operator error, or due to pauses and subsequent restarts in the weld cycle without removing a fed fastener. Stacked nuts are one of the more common errors in nut welding, but it cannot be detected by pin measurement alone.

The Double-Nut Sensor Kit includes a sensor and bracket that attaches to the upper moving head of the welder. The sensor connects to the NVS+ for a second level of protection.

Light Tower

The Light Tower makes production (and faults) highly visible to weld supervisors. The tower can be mounted on the NVS enclosure, the welder, or on weld cell guarding for visibility in robotic weld cells.

With the Light Tower, the operator also can also trigger a “call” signal to the supervisor without slowing down operation.

Power Hopper

The ProLine™ Power Hopper uses an electronic lock to limit access to SEKI Feeder Selector Units (sold separately), increasing accountability and control in fastener refills.

The Power Hopper can be controlled via a password on the NVS+ Advanced Monitor. (The Power Hopper can also be integrated directly with existing PLC units).