Harms & Wende Weld Controls

Harms & Wende is a key supplier of high-quality weld controls, with MFDC control technology that automakers throughout the world ask for by name.

Harms & Wende offers three key families of controls for any resistance welding system.

GeniusHWI MFDC Weld Control

Programmed with Harms & Wende’s high-powered xPegasus Windows-based platform, with high customization to meet almost any challenge. The GeniusHWI family ranges from 250A to massive 3500A outputs. The GeniusHWI controller is available in “Basic” and “Professional” trims to make sure you have the tools you need for complete weld point monitoring.

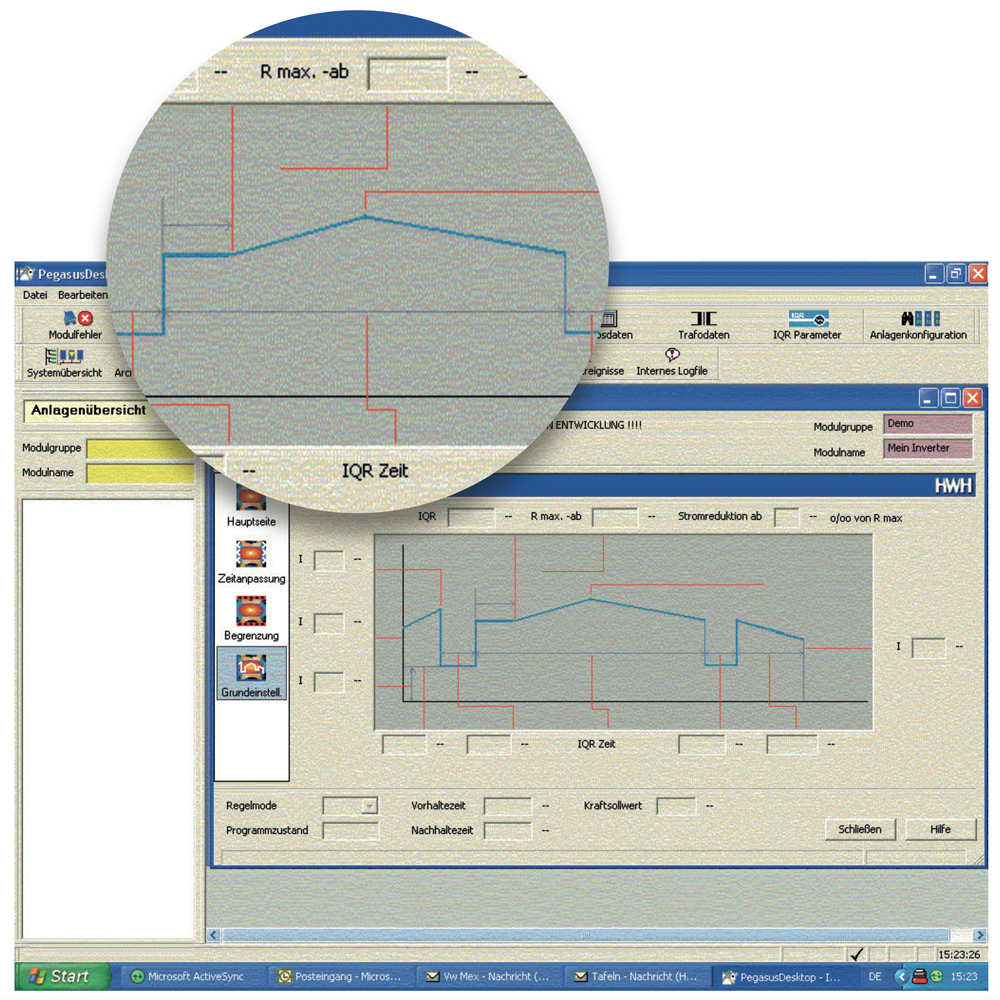

Harms & Wende’s IQflex monitors steel welds in real time for complete IQR. Instead of fiddling with weld parameters, fit the weld to a curve and the weld control will adapt the rest — No calibration necessary.

Basic GeniusHWI Package

- 256 schedules

- 3 main current times (pre-heating, main, post heat time) ISO weld scheme

- Digital 24 V I/O

- Secondary constant current regulation (KSR)

- Electrode management

- Current Upslope, current downslope

- Pulses

- Proportional valve output 0-10 V

- Current limit value monitoring

- Visualisation of measured data through XPegasus (for Windows)

Pro GeniusHWI Package

- 512 schedules

- 3 main current times (pre-heating, main, post-heating time)

- Digital 24 V I/Os

- Constant current regulation (KSR)

- Electrode management

- Current Upslope, current Downslope

- Pulses

- Proportional valve output 0-10 V

- Current limit value monitoring

- Additional Monitoring Inputs: Distance, Current, Voltage, Control Stroke, Resistance

FiliusMFS/MFP Weld Control

Integrated timer and weld controller (in AC and MFDC) for machine-side programming and decentralized operation. The Filius does not require an external PLC or computer to program or operate. While the operation is simple, the Filius is available in several key configurations to allow for advanced control.

Mono Function Filius Series

- 8 schedules

- 3 main current times (pre-heating, main, post-heating time)

- Digital 24 V I/O

- Output for 1 solenoid valve, 1 pre-stroke valve

- Electrode management

- Upslope / Downslope

- Pulses

Classic Filius Series

- 128 schedules

- 3 main current times (pre-heating, main, post-heating time)

- Digital 24 V I/O

- Secondary current regulation (CCR)

- Electrode management

- Stepper function

- Uplslope, Downslope

- Pulses

- Proportional valve output 0-10 V

- Current limit value monitoring current

- Force/pressure program with solenoid valve and proportional valve output 0-10 V

- Program sequence

Multi Function Filius Series

- 2 x 16 schedules

- 3 main current times (pre-heating, main, post-heating time)

- Digital 24 V I/O

- Constant current regulation (KSR)

- Electrode management

- Upslope / Downslope

- Pulses

- 2 x proportional valve output output 0-10 V

- Current limit value monitoring current

SiniusHWI Weld Processor

The SiniusHWI weld processor for the highest level of customization for high-spec applications. The customer brings the PLC and the code to tailor the weld to their specific application, for both AC and MFDC systems. The “processor” name points to the fact that it is taking commands from a customer-supplied PLC for extreme customizations (with code and control written by the customer). The Sinius is also available in 250A to 3500A outputs.

Sinius Advantages

Make with it what you will! The features are what you, the user, can imagine for it.

- 8 internal schedules (unlimited in PLC)

- 10 time segments per schedule or 80 in one schedule

- Secondary current regulation

- Proportional valve output 0-10 V

- Full integration in PLC environment

- Protect your knowledge

- Suitable for almost any PLC

- Customized weld schedules as needed

Contact G.E. Schmidt today to discuss how Harms & Wende can help you get the most out of your application.