ProLine SmartForce

Push Out Test System

The ProLine™ SmartForce Push-Out Test System is the new standard in destructive quality tests for nut and bolt welding. Building on G.E. Schmidt’s success and expertise with the ProLine Push Out Test Stand, the new SmartForce introduces a hosts of key features and improvements to make nut weld testing faster, easier and more traceable.

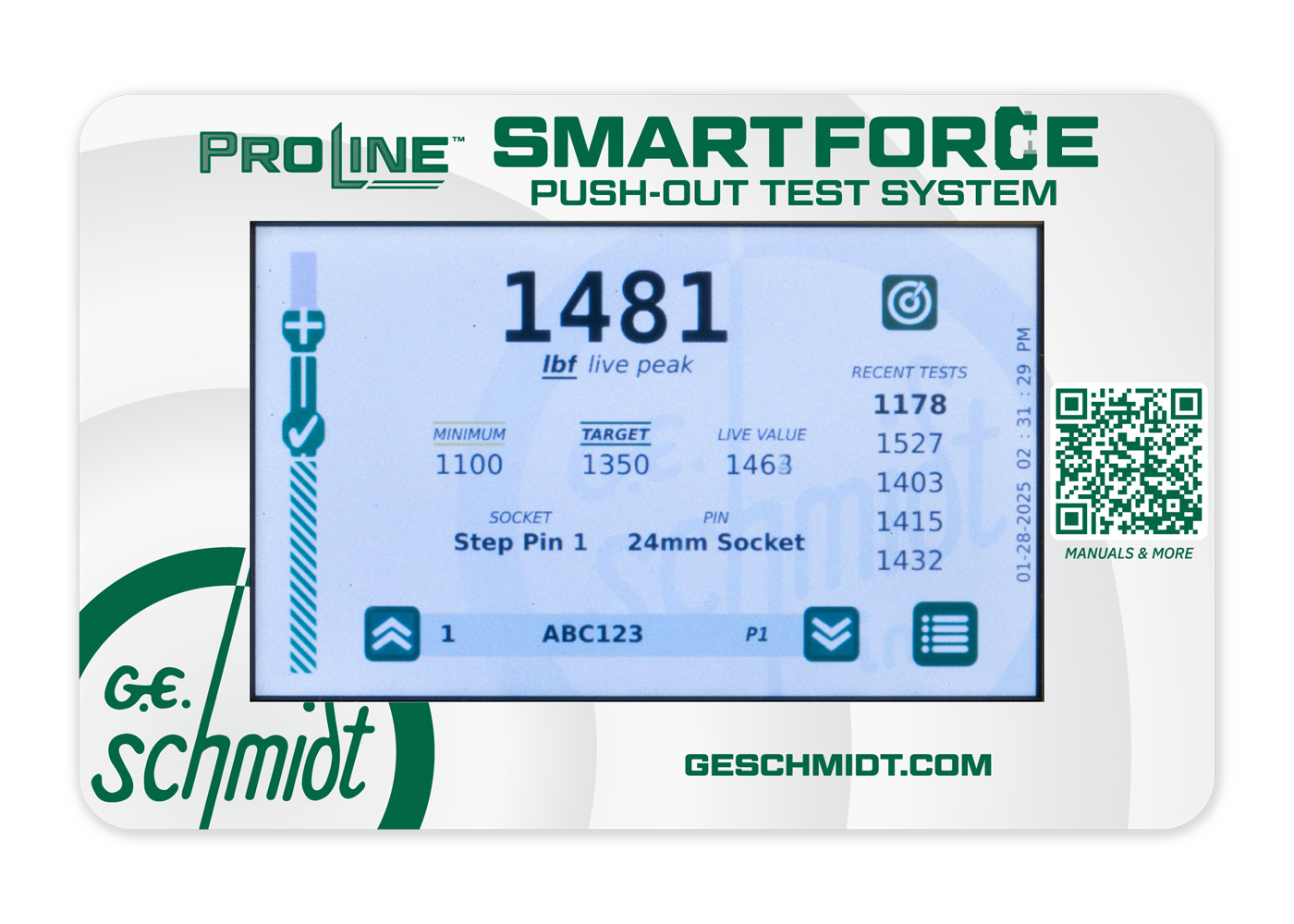

The SmartForce Push-Out Test System features an extremely robust C-frame stand design for maximum precision and safety, as well as a new touchscreen meter with an intuitive user interface, part testing profiles to maintain standards, onboard data logging and tons of other improvements and critical features.

Advanced meter features, now the standard.

The SmartForce Push-Out Test System Meter delivers precision, efficiency, and security for testing applications.

Save customized part profiles for parts and weld locations, including target minimums, safety buffers, testing tool specs, and units of measure. Variable units of measure enhance flexibility across weld tests, solving a common industry challenge.

Its intuitive touchscreen interface replaces outdated LCD numerical displays, simplifying operations. A live graphic shows test progress, along with all of the relevant data — including recent tests.

Data management is seamless: export test data as .CSV files for analysis or email results instantly when connected to a network. Exported data is fully compatible with Excel for sorting and analysis. See an explanation here.

Security is a priority. User-selectable password protection limits profile edits to authorized users, while operators can perform nut and bolt weld tests on different parts without altering critical settings.

Physical buttons, now standard, allow simple profile switching and unit taring, while minimizing screen wear and enhancing the durability of the overall system. This keeps heavy-handed operators off of the screen.

The SmartForce Push-Out Test System Meter combines flexibility, precision, and security, offering an all-in-one solution for advanced testing needs.

Robust enough for nearly any application.

The SmartForce Push-Out Test System C-Stand delivers strength, precision, and flexibility for demanding testing needs.

The newly engineered C-frame combines durability with an exceptional strength-to-weight ratio and a 2.5x safety factor, so you can reach the top of the range of your resistance welding push-out test without deflection. precisely aligned upper and lower platens ensure reliable, consistent testing.

A powerful hydraulic ram precisely measures weld break-off forces, guaranteeing accuracy and meeting minimum thresholds consistently. Choose from standard force capacities of 5,000, 10,000 (standard), or 15,000 pounds force, or request custom options for specialized applications. A pneumatic-hydraulic foot pedal initiation (optional) is also available, as is a two-stage hydraulic hand pump for faster tests.

Interchangeable pins provide flexibility to test various fastener types, including threaded options. Options include step pins, flat heads, concave faces, or custom/OEM-specific designs for unique needs to find the right tool for your nut weld push-out test. Questions about sizing and selection? Just ask.

Versatile sockets, sized using the formula of fastener diameter plus 4 millimeters, ensure consistent results across fastener sizes.

Custom tooling and part holders (optional) enhance safety and convenience, securing heavy, unwieldy parts while keeping operators’ hands safely away from the test zone.

The Smart Force Push-Out Test System C-Stand combines durability, precision, and adaptability, making it the ideal choice for seamless testing across diverse applications.